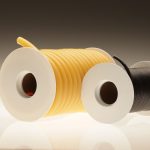

Natural Rubber

Natural Rubber is made from latex sap obtained by tapping rubber trees. It is an elastic material and highly stretchy too. Natural rubber can be vulcanised and converted into different types of rubber products. There are variois types of rubber trees in the South East Asia and Africa that produce latex from which rubber is made

Synthetic Rubber

Synthetic rubber is nothing but an artificial elastomer, which is a polymer. An elastomer, as the name also indicates is elastic. This chemical can be used as a substitute for natural rubber. The properties exhibited are very similar to that of natural rubber. Different kinds of polymers are used to make synthetic rubber. Since different kinds of polymers are used, the properties of synthetic rubber formed are also varied. Hence synthetic rubber can be highly cutomised to the needs of the rubber industry by just altering the inputs used.

Vulcanised Rubber

Processed naturalrubber is called vulcanised rubber. Sometimes it is considered as a different kind of rubber. Natural rubber, as is, can be piy to undustrial or commercial use. Natural rubber has many properties which does not allow it to be used for commercial purpose. For example, it absorbs water, has low tensile strength and is not resistant to abrasion and is also also easily affected by organic reagents too.

So, the process of vulcanisation transforms the properties of natural rubber makes it suitabe for industrial use.

Vulcanisation, thus, is the chemical process used for converting rubber or related polymers into more durable materials by adding sulphur or equivalent curatives. Vulcanised type of rubber material is not so sticky and has superior mechanical properties than natural rubber. The hardness of vulcanised rubber depends upon the quantity of sulphur, which is used during the process and the degree of this hardness determines as to which industry could use the vulcanised rubber for making various products.